How To Set Up Pinion Angle

While it may be common noesis to the veteran gearheads among us, the beingness of pinion offset and all that it entails is potentially strange to those new to the automotive and racing hobby, and with the assistance of Curt Perry at Chassis Applied science in Westward Palm Beach, Florida, nosotros're going to provide a lilliputian 101 education on that very topic then you don't go far a demark…quite literally.

Before we go whatever further, it should be noted the difference between pinion offset and pinion angle. The latter, pinion bending, refers to the vertical relationship betwixt the crankshaft/transmission and the driveshaft and differential. While pinion bending is a Pandora's Box topic of its own that we could easily devote a few thousand words to and emit every bit many opinions as there are readers, the finish goal is to have a perfect line drawn through the driveline, from the centerline of the crankshaft right through the pinion while under load. However, this topic renders a range of thoughts, depending on who you enquire, on the proper angle at rest to reach this perfect angle once the break and other factors come into play under load. Too much angle places the universal joints in a bind, robbing performance, causing unwanted vibrations, and ultimately stressing parts to the breaking point if left uncorrected.

Pinion commencement, meanwhile, is a bit more simplified of a topic. Referring to the lateral position (the side-to-side positioning of the driveshaft in the car), pinion offset is the pinion'due south location relative to the chassis centerline, and is a effect of both the inherent design of many OEM differentials and the need to offset the engine and transmission for a variety of reasons.

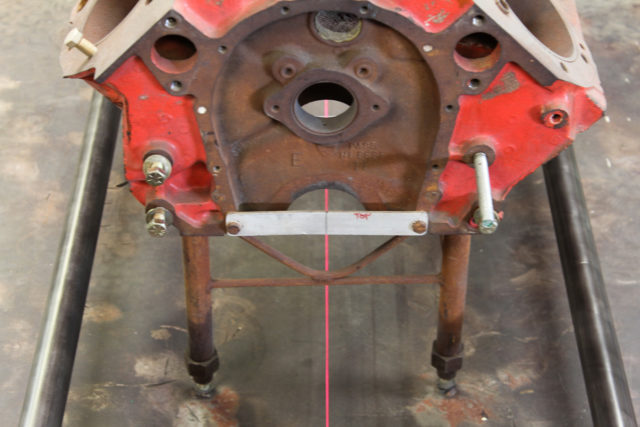

Shown here is the measurement of the center of the pinion out to each axle terminate -- note the ane/2-inch difference side to side, as gear up from the factory.

The vast majority of domestic OEM high-performance applications, exist they GM, Ford, or Chrysler, feature rearends with the pinion offset to the passenger side of the vehicle to lucifer the position of the engine and transmission. Each manufacturer has its reasons for doing this, from fitment of the steering column to providing the commuter more room in the motel. The tried-and-true Ford 9-inch is start 15/sixteen-inch, Ford'southward 8.8-inch housing is outset 9/xvi-inch from the mill, and GM x- and 12-bolts rears are offset 1/two-inch, for example.

The pinion centerline marked on a Ford 8.8 housing.

Regardless of the horsepower range yous're in, the goal is to achieve a straight line through the crankshaft centerline to the pinion, if yous're looking downward from above. Like pinion bending, a driveshaft that's crooked in the auto puts unneeded strain on the driveshaft and driveline components and could effect in vibration and breakage.

If they don't make information technology so that the pinion is commencement that same corporeality, and so the driveshaft is crooked in the car. – Curt Perry, Chassis Engineering

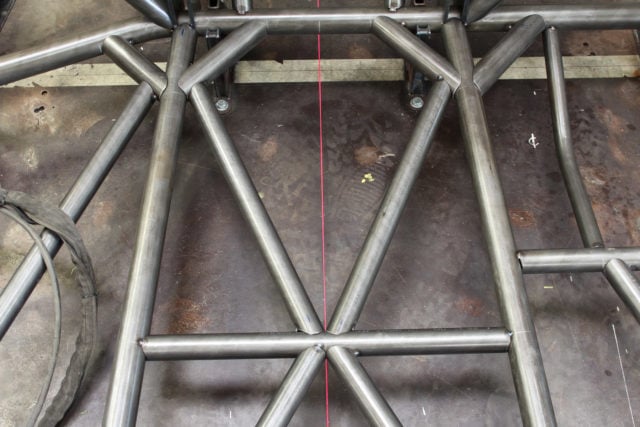

Whether or not you choose to leave the engine, manual, and pinion start relative to the vehicle's chassis is upwards to you — but you lot desire to continue them in line with each other. In drag racing, both trains of thought exist; Chassis Engineering science builds all of its chassis cars with the engine centered, and most purpose-built chassis cars are done equally such. However, there are plenty of examples out at that place of racers offsetting the engine and transmission to provide improve weight balance and handling characteristics at speed. Either fashion works, and then long equally the tailshaft of the transmission and the pinion are lined up when all is said and done.

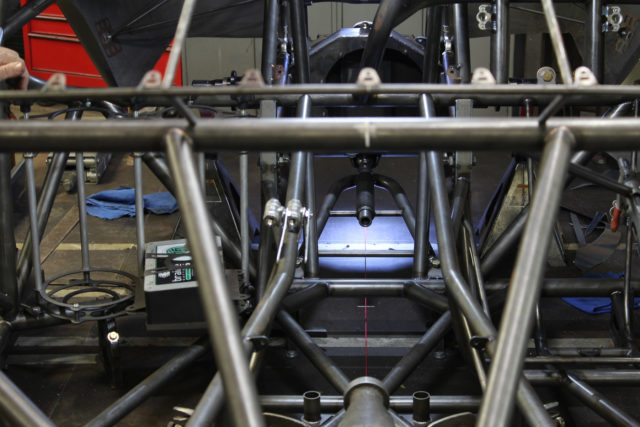

Chassis Engineering science illustrates the centering of the engine block (and therefore the crankshaft centerline) to the chassis.

This, Perry shares, is where the confusion comes along, as racers cut apart factory vehicles for back-one-half chassis jobs and cull to centre the engine — once you do then, the pinion, and therefore the entire housing, have to be moved. With that comes cut of drivers's side beam tube and measuring for the proper beam length to accommodate the adjustment (back-halving the car and plumbing equipment larger wheels and tires, which many of you reading probable are, will necessitate cutting both beam tubes down in order to narrow the housing).

"Where the defoliation comes in is when guys are going to back-half a car — they don't know or realize that the manufacturing plant moves the engine and transmission off to the passenger side. If they don't make information technology and then that the pinion is kickoff that same amount, and then the driveshaft is crooked in the auto.

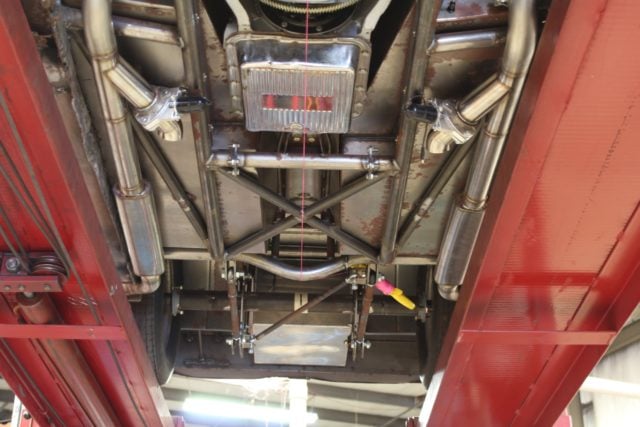

Chassis Technology bach-halved this Chevy Vega and centered the engine and pinion in the process. The string running the length of the motorcar illustrated this location.

"Most GM cars are shifted over half an inch, for instance, so if you aren't moving the motor back to the centre of the car, just you're edifice the rear end as eye pinion, and then it'due south going to be off that one-half an inch," Perry continues. "They need to accept it built so the pinion is half an inch offset to the passenger side to match."

Well-nigh GM cars are shifted over half an inch, for case, so if you aren't moving the motor back to the middle of the motorcar, but you lot're building the rear finish every bit centre pinion, then it's going to be off that half an inch. – Curt Perry

The driveline should, as Perry confirms and a gilt rule Chassis Technology adheres to, always be perfectly inline. While the pop GM and Ford vehicles are largely consistent in showtime, Perry says Chrysler vehicles tin can vary by every bit much as an inch from model to model, requiring extra diligence in measurement and alignment to ensure everything is matched up.

Perry uses the ever-popular Fox-body Mustang to illustrate a typical scenario for a racer modifying the chassis and/or rearend.

"Let's say you take a Play a trick on-body you're going to back-half and you want to narrow the rear and it's on the stock engine mounts. That'due south pretty straightforward — everyone knows they're offset to the passenger side by half an inch, and everybody can keep about their business. The problem is, if yous want to dorsum-one-half information technology and you want to put it on motor plates, the question is, are y'all moving the engine back to the heart of the auto, or are you going to leave it with the one-half-inch pinion offset? That's why we go through the whole scenario with the customer and have them measure everything. Because we don't know if the previous owner did it correctly or non."

This rearend housing has a nigh two-inch starting time from centre.

Of course, accuracy of class is key hither, merely performing this measurement isn't hard. Chassis Technology, every bit does whatever proficient chassis builder, advises using a framerail, a suspension pickup point such as leaf bound mounting locations, or similar to perform your centering (or commencement) measurements. This tin can exist done with a record measure from point-to-point, or with a plumb-bob on the jig or floor with markings to measure to and from. This applies to both the rearend/pinion positioning and the engine location itself, although the engine and transmission location is generally more simplified since y'all can use the front framerails as your measurement point.

Distance from housing end to housing stop (56.five-inches) on the Ford 8.8-inch housing at Chassis Engineering.

"Any good pickup signal that'due south the same on both sides will work. You could go from inside a framerail to inside a framerail a lot of times at the forepart and do the same out by the tailshaft of the transmission. That offset should exist the aforementioned front to dorsum and if it's not and so yous need to effigy out where your pickup points are," Perry shares.

In the rear, Perry explains, "you're better off using the frame more than annihilation else — yous'll accept to drop a plumb-bob off the inside or outside of the rails, drop it downwardly and then measure point to signal."

A mismatched pinion offset, as alluded to earlier, just puts too many stresses from likewise many different angles on the u-joints and bearings, and in due fourth dimension, that mistake will rear its ugly head.

"Your u-joint is going to be doing too many things — if you have some pinion angle in information technology, and the driveshaft is off to the side, at present you're making the u-joint do what it'south designed to do, but it isn't going to be happy about it, because everything is going to be in at an bending. With pinion angle, you lot're shooting to have the driveshaft, under load, in line with the pinion. That way the u-articulation is neutralized and all it'southward doing is driving the auto — it'southward non having to move or flex forward, back, left, or right. If yous have the driveshaft off to one side, now you lot've exacerbated the problem."

A key thing to factor into any change in pinion offset is beam tube length and beam length. If the engine is centered, the pinion also has to exist centered in the chassis. This is where it becomes decision fourth dimension.

The goal with regard to pinion kickoff is to accept the engine and transmission aligned perfectly with the pinion, whether it'southward offset or centered. In the case of tube chassis cars, Chassis Engineering always centers the drivetrain and driveline in the car.

If you opt to leave the offset in the driveline and program to proceed the existing housing, and so you lot tin can order your axles and you're all gear up. If, however, you desire to center things up simply use the existing housing, it becomes a bit more complicated. In order to shift the pinion to the centre, the housing itself has to be moved to the driver's side of the motorcar, leaving the axle tubes uncentered. To compensate, you'll need to measure the housing from the pinion heart out and cut down the driver'south side beam tube. This as well leaves the rider side housing terminate narrower than it was previously. Although at that place are certainly examples out at that place of housings with extra tube welded on, it generally isn't advised, and at this stage, Perry recommends either narrowing the reared overall, or having a custom rearend housing built with the 3rd member centered to the desired length of the beam tubes.

Of form, either approach will crave a custom set of axles — y'all'll want to measure out from the outside of the housing end to the center of the pinion on each side and gild a new set up of accordingly.

A custom housing or i designed for center pinion places the third member off-center in relation to the "pumpkin" of the rearend housing, thus shifting the pinion and band gear to the driver's side of the housing. In doing so, the housing itself can be symmetrical and the axle tubes the same length. Your axles, nonetheless, will still be of uneven length.

In truth, there's no science to pinion offset nor is there a right way or a incorrect way — heart or kickoff pinion — but like anything else on a racecar, you lot tin can save yourself a lot of headache down the route by doing your homework up front, asking the right questions of the right individuals, and being deadly accurate with your measurements and calculations to get it all lined up the commencement time. While it is a simple concept, it's most definitely non an like shooting fish in a barrel set if y'all get it wrong.

How To Set Up Pinion Angle,

Source: https://www.dragzine.com/tech-stories/pinion-offset-guide-and-how-to-with-chassis-engineering/

Posted by: tilleysamium.blogspot.com

0 Response to "How To Set Up Pinion Angle"

Post a Comment